May.03.2023

Part II: Logo Design Effects

In addition to the common logo effects introduced in Part I , the following sections will introduce the use of mirror-polished/glossy engraved logos and flat logos. Each picture is linked to a video that showcases the logo effect from different angles.

Flat Logos - IMD logos on Plastic

IMD (in-mold decoration) is a popular technique for high-end plastic products. But creating a real IMD effect is not feasible in model-making. However, we can use the following three alternative methods to emulate the IMD appearance:

1. Chrome-plated logo on the top surface with clear coating to simulate IMD

2. Chrome sticker logo on the backside of transparent plastic material

3. Silver back printed logo (~60% mirror-polished) on the backside of transparent plastic material

Note: Simulating the IMD effect in model-making is a complex process with a low yield rate, which leads to higher costs and longer lead times.

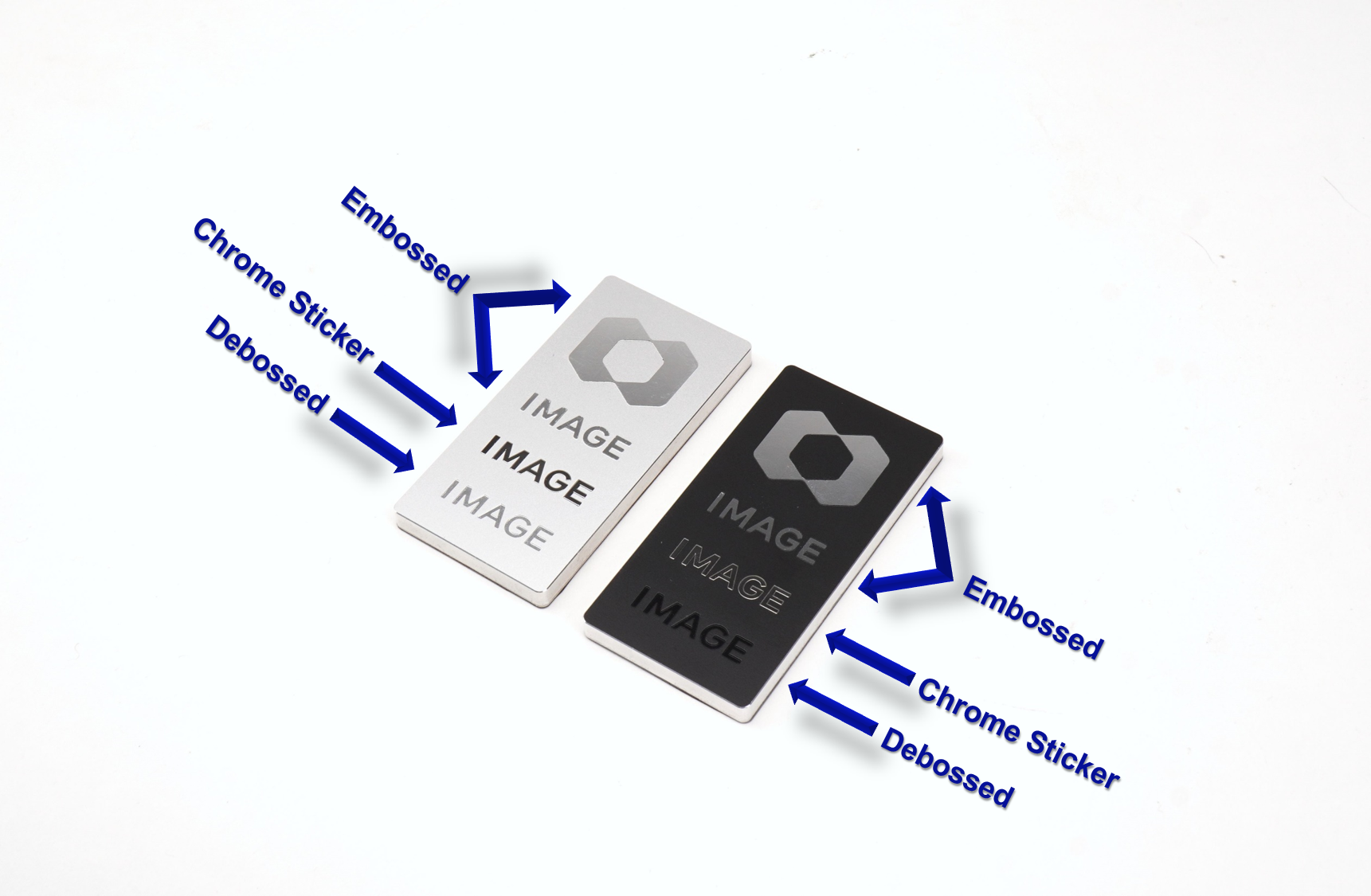

Embossed Logos - Mirror-Polished logo on Metal: Diamond-cut with clear anodization (left) and with black anodization (right)

The embossed area or logo is usually 0.2-0.5mm higher than the product's surface. The logo can be made with a mirror-polished effect to increase the contrast of the embossed logo. This mirror-polished effect is achieved through diamond-cut machining, which saves on polishing costs.

Note: Diamond-cut can create a high-polish surface, but there will be slight machining marks, especially on large surfaces.

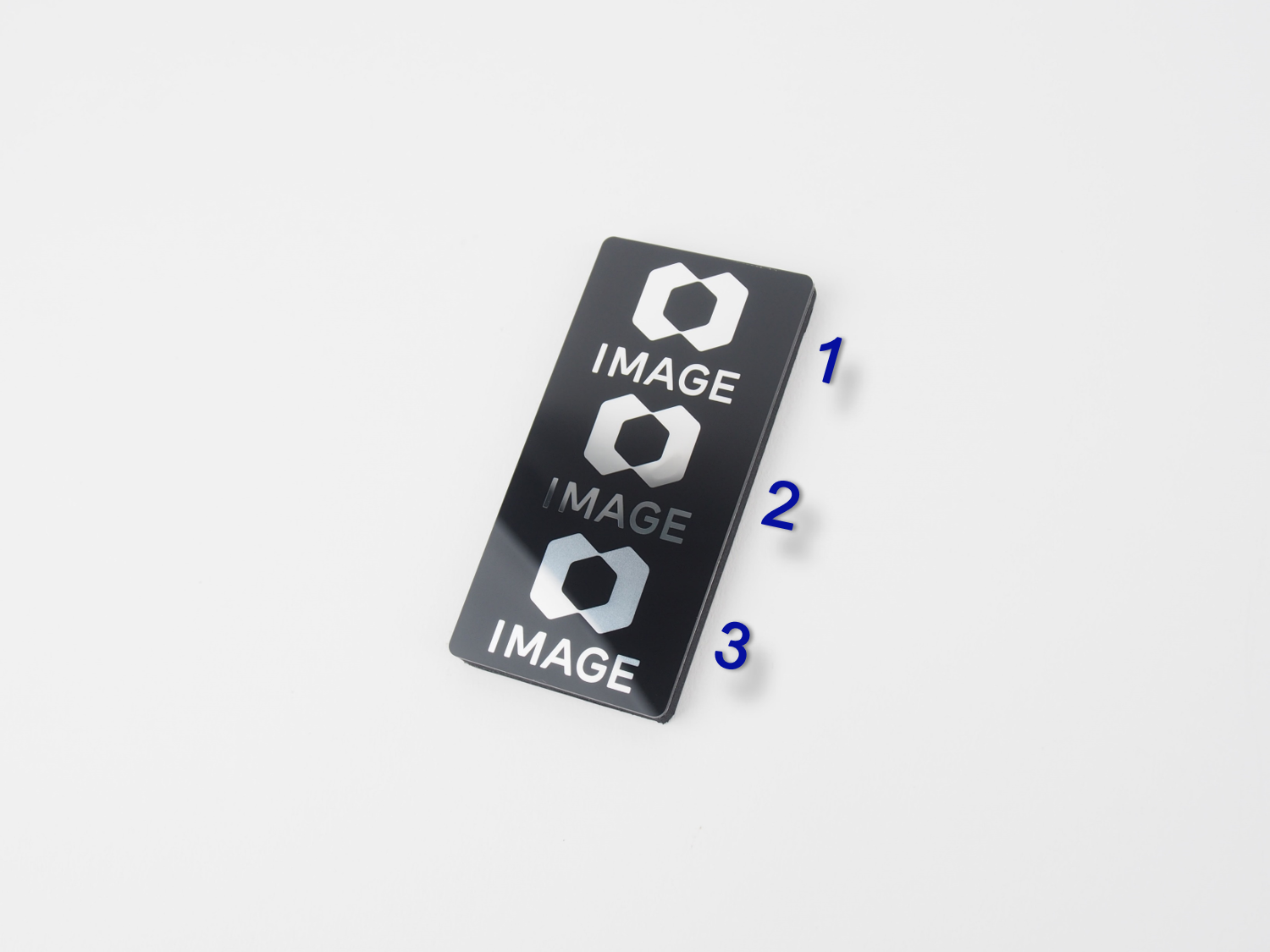

Mirror-Polished logo using Chrome Sticker: Chrome sticker on a silver surface (left) and black surface (right)

Chrome stickers are commonly used to achieve a mirror-polished effect in different colors and can be applied to flat, debossed, and embossed surfaces. However, there will be parting lines around the logo because the tolerance of the chrome sticker is relatively loose.

Note: Chrome stickers can be applied to both plastic and metal surfaces and can create a similar effect to physical vapor deposition (PVD) on metal surfaces.

Debossed Logos - Mirror-Polished logo on Metal: Debossed logo with a glossy finish on clear anodization (left) and with black anodization (right)

Polishing a debossed surface can be challenging. To maintain a high-gloss finish on the debossed area of metal parts, we can use precision CNC machining, followed by surface treatment with metal.

Note: The polishing effect is not comparable to diamond-cut machining, and there may be slight machining marks at the bottom of the logo.

Debossed Logos - Glossy logo on Plastic

During mass production, an embossed logo is made on the mold, which creates a debossed logo on the molded part. As in-mold embossed logos are easy to polish, many products use debossed logos with a glossy finish in mass production. But simulating this The effect in model-making can be challenging since it is difficult to polish a debossed surface.

Note: Clear coating is used to make the debossed logo with a glossy finish in model-making. However, there will be paint buildup at the corners of the logo.